Farm transportation, whether it is traditional, simple, mechanized, or advanced, transport is an essential component as well as in crop production. This includes the practice of transporting the crops to the market and ensuring the preservation of crop yield and quality.

THE KALUMPANG FARM

In Kalumpang Farm, we have the modern facilities with employ high technology approach to ensure the system is running effectively and efficiently. Design and management of livestock facilities and equipment require more and more professional knowledge and new technologies. Compared with other biological structures such as residential buildings, livestock facilities present unique challenges in terms of heating, ventilation, air conditioning, air quality, physical environment for better animal welfare and production, waste handling and treatment, environmental and community relation issues.

Farm

- Pullet Houses

- Layer Close-Houses

- Organic Fertiliser Plant

- Feed Mill Plant

- Egg Grading and Storage Area

- Administration Area

- Staff Quarters and Hostels

- Changing Room

- Canteen and Surau

Transport

Automation

Every house is equipped with a computer that provides the farm supervisor or farm manager with all the necessary information on egg production, feed and water consumption, temperature and mortality etc. The computer system will help the farm manager to manage the chicken houses more effectively and efficiently.

The computer system will record the following:

- House temperature

- Ambient Air temperature

- Outside temperature

- Feed consumption

- Water consumption

- Egg production

The computer system also controls and monitors the following:

Ventilation:

Based on the house temperature, outside temperature, age and weight of the birds, the system will determine the degree of ventilation needed. The system will also ensure that the air inlets are always in such a position that the birds are supplied with fresh air at the right speed.

Cooling:

Hot air outside the house will adversely affect production. The system will not only control cooling on the basis of temperature, but also on the basis of admissible air humidity at a particular temperature.

Lighting:

The computer is equipped with a programmable time switch and lighting control level. The system will help increase egg production and optimize feed and water consumption.

Feeding:

The computer combined with an intelligent feeding schedule allows the farm supervisor to supply the right amount of feed per tier, per cycle and per day. No excessive feed is supplied to the birds that can lead to unnecessary cost increase.

Water Intake:

Water consumption by the birds can also be controlled by the system. Disturbances and interruptions in the water supply of each tier are immediately signaled. Sufficient water intake will produce acceptable dry matter content of the manure.

Manure Drying:

The ventilated housing system provides the air flow across the manure belt to help produce drier manure and leads to better environmental conditions.

Egg Gathering:

The system will be able to determine the speed of the egg belts and the speed of the egg grader. This control will help minimize egg breakages.

Alarm System:

The system will act as a “watchdog timer”. The system will activate the alarm in the event of power failure, deviations in temperature, water consumption, feed consumption and stock fall below minimum level.

Spray Facility and Wheel Dip for Motor Vehicles

2 spray facilities in two different locations have been built. The first spray facility is at the entrance to the layer houses. The second is at the entrance to the pullet houses. All motor vehicles going into these two areas will have to pass through the wheel and spray area to ensure that they do not carry pathogens that will contaminate the whole farm.

Changing Room and Spray Facility for Farm Workers

The Kalumpang farm has been divided into discrete operating units. Workers from one operating unit are not allowed to enter the other operating unit. These workers are supplied with different coloured uniform for easy identification. Before they enter into their respective operating units, they have to pass through the spray section. This practice is mandatory for all workers to ensure that they do not carry pathogens or potential disease to the farm.

Grading and Packing Centre

The egg grading and packing station is air conditioned. Two units’ high-speed grading machines are used to grade the eggs according to weights. The air condition environment provides a comfortable setting for the workers to work in. It also enables the eggs freshness to be maintained longer.

Water Tanks

The farm has water storage of 719.590 liters of water. The water source for the farm comes from under-ground tube well. The water is pumped to the receiving tank before it is transferred to a treatment plant. Treated water is then stored in a tank before it is distributed to the respective houses.

Media and Laboratory Room

Under the bio-security and HACCP protocols, there is a need to regularly and consistently monitor the farm for pathogens and to ensure their absence from the farm operations. For this purpose, it requires laboratory testing. The farm has set up a laboratory with all the necessary tools and equipment to carry out the required testing.

Executive Quarters and Workers’ Hostel

Four units of 3-bedroom quarters and four units of 2-bedroom quarters are erected for the executives. These units are equipped with bathrooms and kitchens. The managerial quarters are air-conditioned.

Two units of double-storey hostels had been built in the farm compound. Each storey can accommodate about 20 workers. One unit is designated for men and the other is for women workers.

Training Room and Training Simulator

The farm has set-up one training room and two close-house simulators to train the employees to acquire the fundamental knowledge of close-house system. This will enable them to manage the equipments more effectively and efficiently.

Feed Mill

The existing feed mill in Kalumpang is capable of producing about 5000 metric tons of feed a month. The feed production is used to provide feed to its farm as well as to cater a small portion of sales to third party. The feed mill is equipped with the state of the art machines to achieve greater efficiency and also to ensure that quality feed free from contaminants are produced to meet the feed requirements of the farms.

The following types of feed will be produced for its consumption:

- Starter feed

- Grower feed

- Developer feed

- Pre-Layer feed

- Layer 1 feed

- Layer 2 feed

- Designer Eggs Formulated Feed

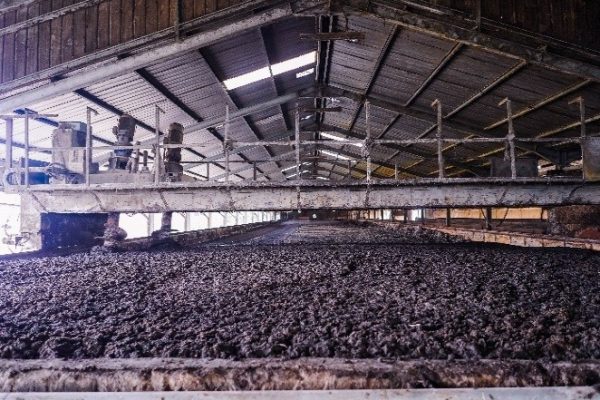

Organic Fertiliser Plant

One major by-product of the layer industry is chicken manure. The total of fresh manure for Kalumpang farm is around 30,000 MT per year. Raw chicken manure is potentially a health hazard if it is not disposed off in an efficient manner. It will also become a breeding ground for flies and emits undesirable smell.

The farm has set-up an organic fertilizer plant for the purpose of converting the chicken manure into bio-organic fertilizer and at the same time to bring in additional revenue to the farm through value-added operations on the raw materials.

Adopting the Korean Composting Technology, SASB utilized the chicken manure obtained from its layer operation, combines with selected carbon sources and suitable micro-organisms to transform the waste into nutrient rich organic fertilizer with necessary beneficial microorganisms.

SASB brands its bio-organic fertilizer as JUTANI. that provides a rich organic matter and required nutrients that are needed for sustainable growth for plants, vegetables and flowering / fruiting plants. It is indeed a product for all purpose.

JUTANI comes in three different brands namely :-

Jutani – A mesh form Bio- organic that are fully composted from chicken manure.

Jutani Plus – Pelletized for easy application and slow release

Jutani Super – Combined with selected carbon sources and necessary beneficial microorganisms to transform the chicken manure into a nutrient rich organic fertilizer.

QUALITY CONTROL

ECO-CENTRE

(Processing organic fertiliser from chicken manure)

Packing of finished product (fertiliser)